Quality Control Standards

Quality figures determine a baseline for

the fundamental values in all aspects of our manufacturing;

- ISO 9001 Certificate.

- (Effective Date:2022-01-27

- Expiry Date:2025-01-26).

- ISO 14001 Certificate.

- (Effective Date:2022-09-13

- Expiry Date:2025-11-05).

- IPC Qualified Manufacturers

- Listing (QML) Authentication.

- Total Quality Management.

- Zero Defect Program.

- Selected Vendor Partnership.

- Periodical Reliability Test.

Quality Control & Assurance

| Quality Control & Assurance Department |

|---|

Incoming & Quality ControlAQL Standard Sampling Inspection. |

In Process & Assurance SystemOnline QC (Cleaning, Printing , Chip Position). |

Out Going & Quality ControlFunctional Testing (Electronic, AC/DC, Pin Terminal, Mechanical). |

Reliability Conditions

| LCD Module ( Consumer ) | ||||

|---|---|---|---|---|

| No | Item | Test Condition | Applicable Standard | |

| 1 | High Temperature Storage | Keep in 80±5°C 240 hrs | MIL-202E | |

| 2 | Low Temperature Storage Test | Keep in -30±5°C 240 hrs | MIL-202E | |

| 3 | High Temperature/Humidity Storage Test | 1. Storage 240 hrs 60°C, 90~95%RH (Polarizer may fail in this environment) Or 2. Storage 96~100hrs 40±2°C,90~95%RH |

MIL-202E | |

| 4 | Temperature Cycling Storage Test |

-20°C → 25°C → 70°C → 25°C

|

MIL-202E | |

| 5 | Vibration Test(Packaged) | 10~55Hz(1 Minute)1.5mm direction each time by X,Y And Z Direction x (Each 2hrs) | MIL-202E | |

| 6 | Drop Test(Packaged) | Packing Weight (kg) | Drop High (cm) | MIL-810E |

| 0 ~ 45.4 | 122 | |||

| 45.4 ~ 90.8 | 76 | |||

| 90.8 ~ 454 | 61 | |||

| Over 454 | 46 | |||

| 7 | ESD Test | Air Discharge: Apply 2KV with 5 times discharge for each polarity +/-. |

Contact Discharge: Apply 250V with 5 times discharge for each polarity +/-. |

IEC 61000-4-2 |

Testing location: |

Testing location: 1. Apply to bezel. 2. Apply to Vdd, Vss. |

|||

◎Result Evaluation Criteria :

Under the display quality test conditions with normal operation state. Do not change these

conditions as such changes may affect practical display function.

(Normal operation state)

Temperature:+20~30°C

Humidity:50~70%

Atmospheric pressure:86~106Kpa

◎Please refer to the product specification for the exact reliability conditions.

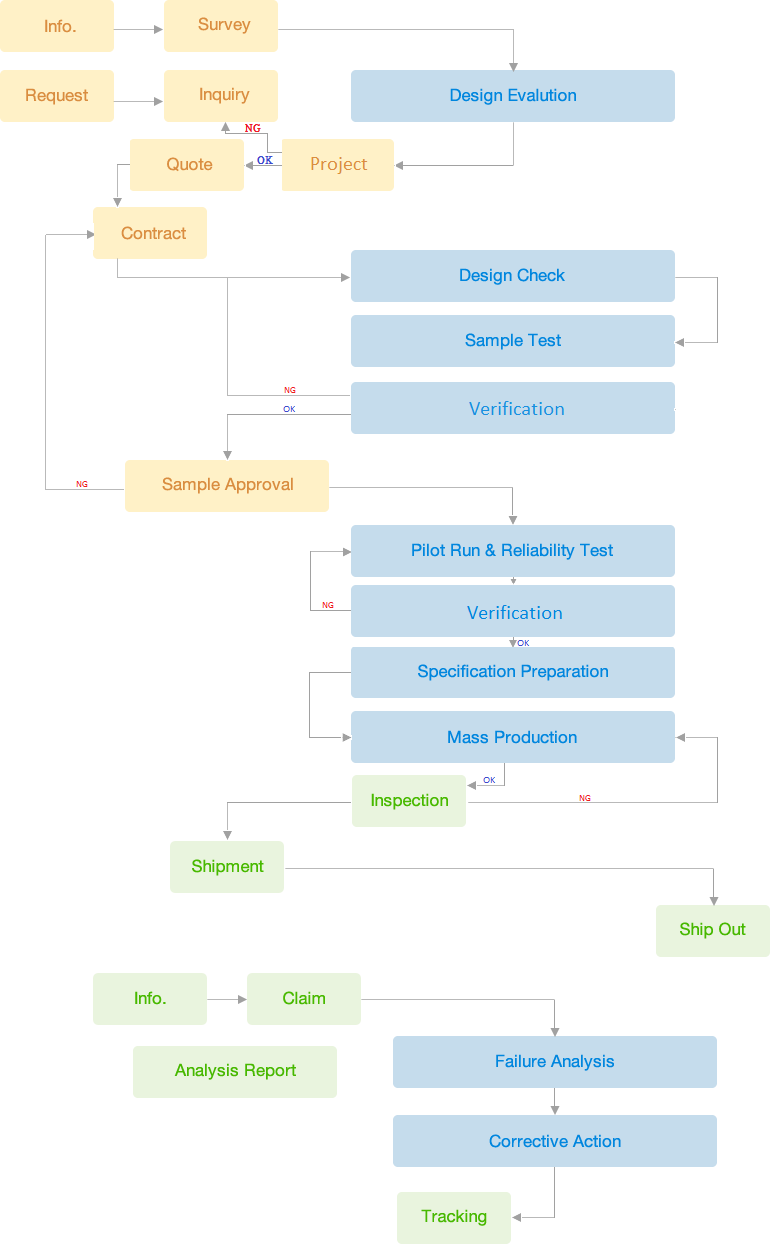

Quality Control and Assurance Standards

| Item | Customer | Sales | R&D | Q.A | Manufacturing | Product | Control | Purchase | Inventory | Control | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Marketing & Design |  |

||||||||||

| Sample Approval | |||||||||||

| Pilot Run & Mass Product | |||||||||||

| Ship Out | |||||||||||

| Sales Service | |||||||||||

| Q.A Activity |

|

||||||||||